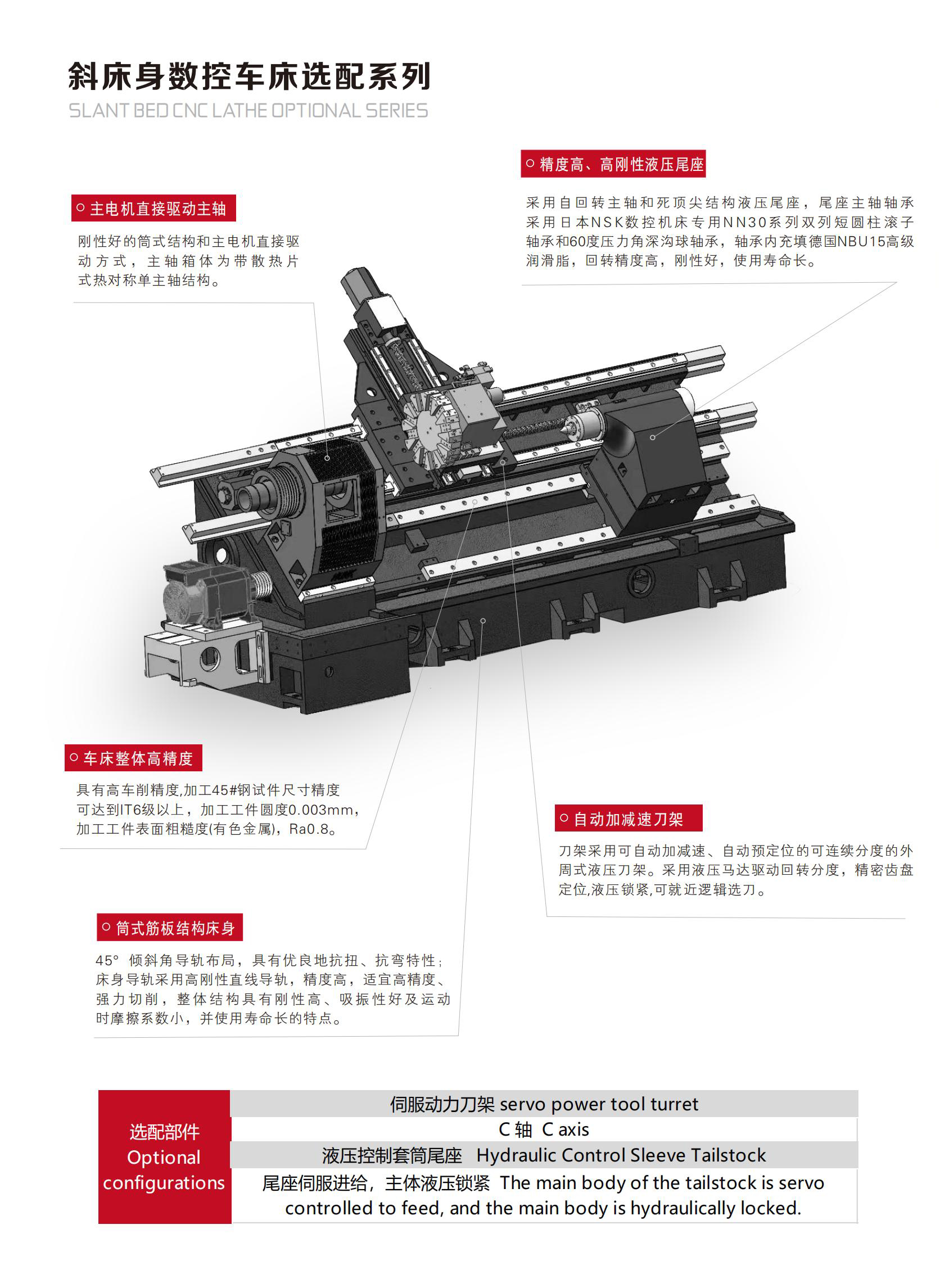

The overall bed structure is cast at a 30/45 degree angle, ensuring high rigidity and bending and shock absorption performance of the foundation components.

By clamping various types of discs, shafts, and parts in one go, it is possible to complete the machining of grooves, inner (outer) holes, spherical shapes, R-angles, curved surfaces, conical surfaces, end faces, single and multi head male and female threads.

The external protection of the machine tool adopts a fully protective structure design, which is easy to operate, safe and reliable, and aesthetically pleasing

X. The feed in both directions of Z adopts high-precision and high-strength internal circulation double nut preloaded large lead ball screw, with high feed speed.

| SPECIFICATION | CK-32L | CK-36L | CK-40L | CK-50L | CK-63L | CK-80L |

| MAX.SWING OVER BED | 320 | 360 | 400 | 500 | 650 | 800 |

| MAX.SWING OVER SLIDE | 160 | 160 | 220 | 320 | 500 | 640 |

| MAX.PROCESSING LENGTH | 350 | 350 | 450 | 550 | 890 | 890 |

| MAX.CUTTING DIA.(DISC TYPE) | 200 | 254 | 360 | 420 | 630 | 800 |

| MAX.BAR DIA. | 40 | 45 | 51 | 51 | 75 | 90 |

| SPINDLE SPEED | 4000 | 4000 | 3500 | 2500 | 2200 | 1500 |

| SPINDLE NOSE ISO FORM | A2-5 | A2-5 | A2-5 | A2-6/8 | A2-8 | A2-11 |

| THRU-HOLE DIA. | 41 | 56 | 56 | 66/82 | 86 | 112 |

| CHUCK DIA. | 160(6”) | 200(6”) | 200(8”) | 250(10”) | 320(12”) | 380(15”) |

| MOTOR POWER | 3.7servo | 3.7/5.5servo | 5.5/7.5/11servo | 11/15servo | 18~22servo | |

| BODY STRUCTURE | 30°integrated | 30°integrated | 45°integrated | 45°integrated | 30°integrated | 30°integrated |

| X AXIS TRAVEL | 220 | 200 | 210 | 260 | 410 | 410 |

| Z AXIS TRACEL | 350 | 350 | 450 | 550 | 860 | 860 |

| X/Z AXIS RAPID SPEED | 24/24 | 24/24 | 24/24 | 24/24 | 18/18 | 18/18 |

| TYPE | 63-8T | 80-8T | 100-8T | 160-8T | 160-8T | |

| TOOL SIZE | 20*20 | 20*20 | 20*20 | 25*25 | 25*25 | 25*25 |

| TAILSTOCK SLEEVE DIA. | 52 | 52 | 52 | 75 | 150 | 150 |

| TAILSTOCK SLEEVE TRAVEL | 60 | 60 | 60 | 100 | 150 | 150 |

| TAILSTOCK SLEEVE TAPER | MT4 | MT4 | MT4 | MT5 | MT5 | MT5 |

| PROCESSING PRECISION | IT6 | |||||

| REPOSITIONING PRECISION | X:0.006,Z:0.008 | X:0.006,Z:0.01 | ||||

| ROUGHNESS | Ra.≤0.8 | Ra≤1.25 | ||||

| N.W(KG) | 1500 | 1700 | 2700 | 3500 | 5500 | 5600 |

| DIMENSION(m) | 1.6*1.4*1.6 | 1.8*1.6*1.6 | 2.8*1.6*1.6 | 3.1*1.8*1.8 | 3.8*2.2*2.2 | 3.8*2.2*2.2 |

The casting wood type of this machine tool adopts aluminum wood combination, resin sand casting, worktable HT300, and the rest are TH250. And after two manual aging treatments, it has good stability, high strength, and stable and reliable accuracy in all a

The Casting Wood Type Of This Machine ToolAdoptsAluminum Wood Combination, Resin Sand Casting

The Casting Wood Type Of This Machine ToolAdoptsAluminum Wood Combination, Resin Sand Casting

The Casting Wood Type Of This Machine ToolAdoptsAluminum Wood Combination, Resin Sand Casting

The Casting Wood Type Of This Machine ToolAdoptsAluminum Wood Combination, Resin Sand Casting

Jinan Hankui International Trading Co., Ltd.

技术支持:传承网络